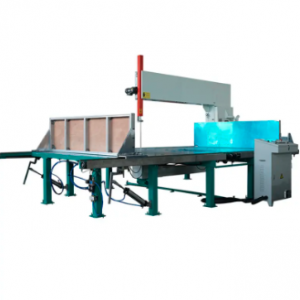

Abasiki begwebu ezithe nkqozizixhobo ezixabisekileyo kumashishini ahlukeneyo afana nefenitshala, ukupakishwa kunye nemoto.Isika amagwebu ngokuchanekileyo, ngokufanelekileyo nangokutyibilikayo.Ukugcinwa rhoqo kubalulekile ukugcina oomatshini bekwimeko ephezulu yokusebenza kunye nokuqinisekisa ubomi obude.Kweli nqaku, sixoxa ngeengcebiso eziphambili zokulondoloza abasiki be-foam abathe nkqo.

1. Gcina umatshini ucocekile: Ukucoca rhoqo kubalulekile ukususa naluphi na uthuli, i-debris okanye i-foam particles enokuthi iqokelele kumatshini.Sebenzisa ilaphu elithambileyo okanye ibhrashi ukucoca itafile yokusika, iincakuba, kunye nezinye iindawo.Ziphephe iikhemikhali ezirhabaxa njengoko zisenokonakalisa umphezulu womatshini.

2. Lubricate iindawo ezihambayo: Ukuthambisa kubalulekile ukugcina ukusebenza kakuhle komatshini.Jonga imiyalelo yomenzi ukuze ubone indawo yokuthambisa kwaye usebenzise isithambiso esicetyiswayo.Faka i-lubricant kwiibheringi, izikhokelo kunye nezinye iindawo ezihambayo zokunciphisa ukukhuhla kunye nokuqinisekisa umsebenzi ofanelekileyo.

3. Jonga i-blade: i-blade yinxalenye ephambili yeumatshini wokusika amagwebu nkqo.Jonga ibhleyidi rhoqo ukuze ubone naziphi na iimpawu zokuguga okanye zokonakala.Ukuba incakuba ibuthuntu okanye ichotshiwe, ayinakusika igwebu ngokufanelekileyo.Ukuba kuyimfuneko, buyisela i-blade kwaye uqinisekise ukuba ihambelana ngokufanelekileyo kwaye iqiniswe ngokukhuselekileyo.

4. Lungisa ukutsala ucingo okanye i-blade tension: Ngokuhamba kwexesha, ucingo lokusika okanye i-blade tension inokufuna ukulungiswa.Uxinzelelo olungafanelekanga lunokubangela amanxeba angalinganiyo okanye umonakalo owenziwe ngamagwebu.Qhagamshelana nencwadana yemigaqo yomatshini ukumisela uxinzelelo olufanelekileyo kwaye wenze uhlengahlengiso oluyimfuneko.

5. Hlola ukudibanisa kombane: Ukudibanisa kombane kudlala indima ebalulekileyo kumsebenzi womatshini.Jonga iingcingo, izihlanganisi, kunye nonikezelo lwamandla rhoqo ukuze uqiniseke ukuba akukho ziqhagamshelo okanye iingcingo eziqhawukileyo.Naziphi na iingxaki kufuneka zisonjululwe ngokukhawuleza nguchwepheshe oqeqeshiweyo.

6. Yenza iitshekhi zesiqhelo zokulondoloza: Yenza ishedyuli yolondolozo rhoqo kwi-vertical foam cutter yakho.Oku kufuneka kubandakanye imisebenzi efana nokujonga amabhanti, iigiya kunye neenjini zeempawu zokuguga okanye ukonakala.Kwakhona, jonga iimpawu zokhuseleko ezifana namaqhosha okumisa unxunguphalo kunye nabalindi bokhuseleko ukuze uqiniseke ukuba bayasebenza.

7. Qeqesha i-Operator: Abaqhubi abaqeqeshwe ngokufanelekileyo babaluleke kakhulu ekusebenzeni okukhuselekileyo nokusebenzayo kwe-foam cutter emileyo.Banike uqeqesho kubasebenzi bakho malunga nendlela yokuwusebenzisa kakuhle umatshini, kubandakanywa ukugcinwa kwawo kunye neenkqubo zokhuseleko.Abaqhubi bayakhuthazwa ukuba baxele naziphi na iingxaki okanye izinto ezingaqhelekanga ezifunyenwe ngexesha lokusebenza.

Ngokulandela ezi ngcebiso zogcino, unokugcina umsiki wakho othe nkqo we-foam usebenza kakuhle nangokufanelekileyo, unciphisa ixesha lokuphumla kunye nokwandisa imveliso.Ukugcinwa rhoqo akubandisi nje kuphela ubomi bomatshini wakho, kodwa kukwaphucula umgangatho wokusikwa kwamagwebu akho.Khumbula ukudibana nezikhokelo zomenzi kwaye ufune uncedo lwengcali ukuba luyafuneka.Ngokhathalelo olufanelekileyo kunye nokugcinwa, umsiki wakho othe nkqo we-foam uya kuqhubeka ukuba yi-asethi ethembekileyo kwishishini lakho.

Ixesha lokuposa: Jun-28-2023